Botanical Solutions, nonchalantly, high performance.

Last week I attended a very special shareholder’s meeting. It started as very much all other these kinds of meetings. a white staircase lead to a white door with the logo of Botanical Solution (BSI) that opened to a white hall, another white door lead to a perfectly white room with a whiteboard and white table decorated with a plethora of sweets cookies and water.

The meeting started with a black coffee and the black TV being turned on to show a crisp PowerPoint presentation with the latest achievements of BSI, a very discreet start-up that is using lab-grown Quillay to manufacture one of the most sought-after components for the Pharma industries, the elusive QS-21. Diego Ibañez (CFO) and Gaston Salinas (CEO) walk us through the number of awards they have received around the world, especially in California where Gaston is currently based. They told us about the plant expansion from 120mt2 a few years back to the 1400mt2 implemented today as an R&D and manufacturing facility. In full swing, BSI employs 85 people to grow, keep, and process, tens of thousands of Quillay plants per month that then go to the R&D department or are packaged and sent to customers around the globe.

The conversation started to pick up with questions about volume, market-entry, finances and eventually… new products. This was the point everyone was waiting for because if you know this team you know they are always on the look for something big. So, Diego, nonchalantly as someone who knows that has the tools to disrupt a whole industry, opens up the issue by describing the very positive impression -an understatement- that the visitor from one of the biggest supplier companies in pharma has taken home after –again, nonchalantly said- coming all the way from the Uk and spending one week checking BSI facilities and offering them a collaboration agreement on the spot.

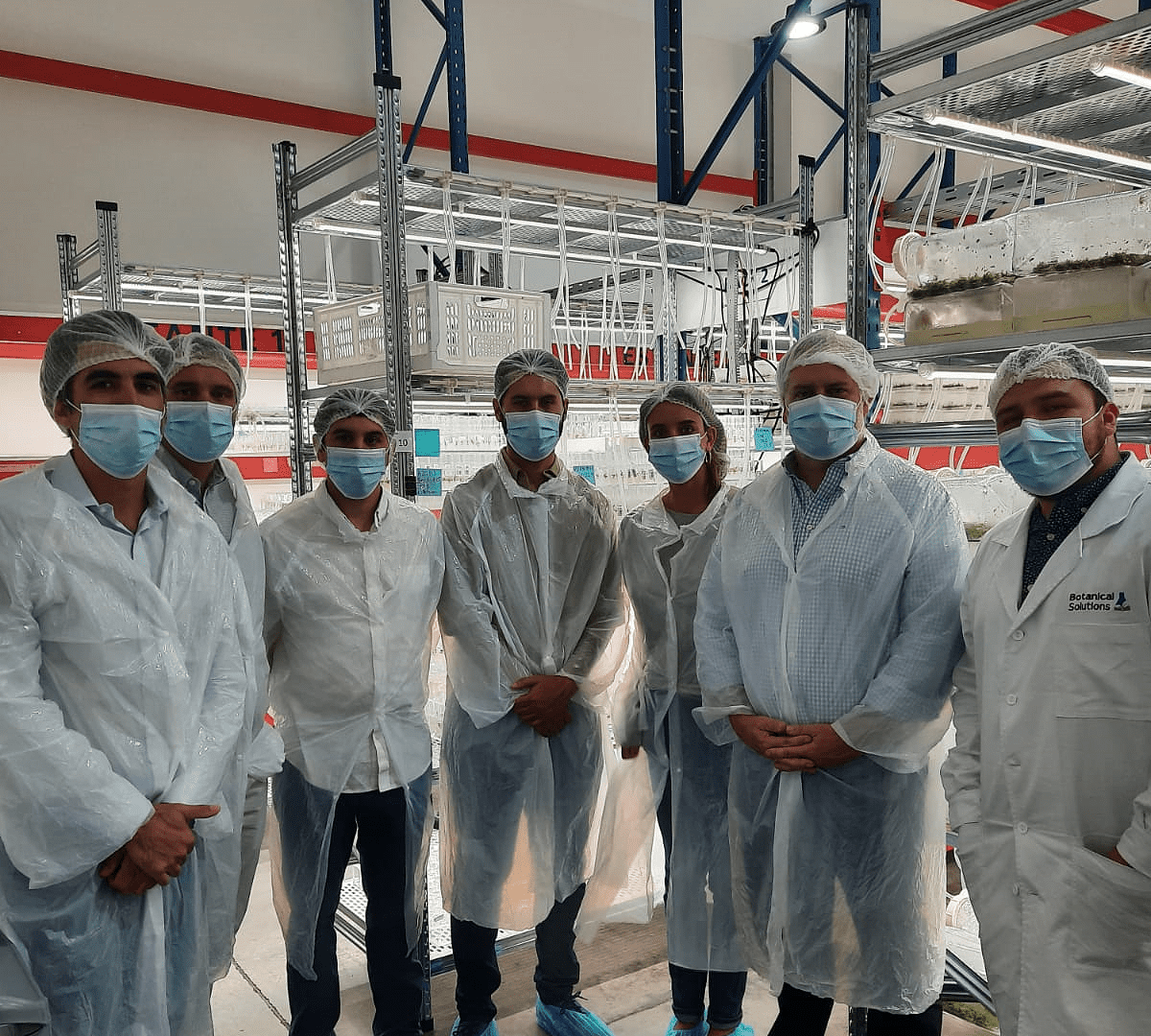

The reason the visitor was very happy about the visit would become clear a few minutes after when we changed the comfort of the white room and cookies for a short walk to the lab. The door opened and we were transported from the scorching hot weather of Santiago in January to a “permanent spring”, the ideal condition not for visiting shareholders but for the impressive inhouse forest BSI has developed. You see, the industry relays on adult Quillay trees to extract QS-21, but BSI has developed and protected a proprietary process to extract this component from plants in the early stages of life. Shorting the processing time from years to weeks, achieving a higher grade product with a constant supply and making the process fully sustainable. The forest consisted not only of plants but also of a little army of highly trained technicians and scientists working with state-of-the-art technology.

But why a pharma executive would fly all the way down to Chile to check on a local start-up? Well, because of the vision and impact of BSI it is far from being local. The new product of BSI which is also based on the QS-21, is an Adjuvant, an ingredient for vaccines that creates a stronger immune response helping the vaccines, like the ones for COVID, to work better. This ingredient is facing a supply crisis in the short term and BSI could hold the key for a steady supply of QS-21 at a global scale.

One last point was made before we had to come back to our regular lives. We quickly jump into the R&D department where they show us new high-demand components being extracted from the same plant, Quillay, thus deepening the value created around their current set-up and also, how they are scaling their proprietary process of extracting industry dependant components to other 100+ plants, expanding their IP and impact into unforeseen territories.

I understand what the Pharma executive from the UK must have experienced visiting BSI, It is very seldom nowadays to get your head blown increasingly during a single day, but I think is the same effect the whole Agro and Pharma industries are feeling every time they get a look on BSI.